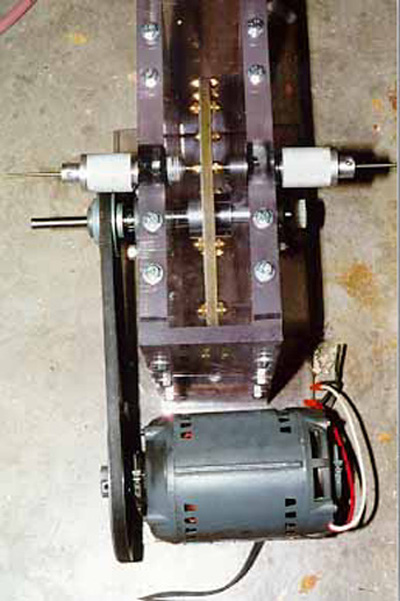

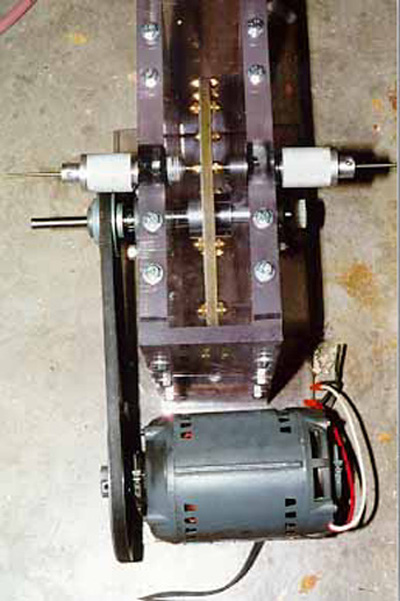

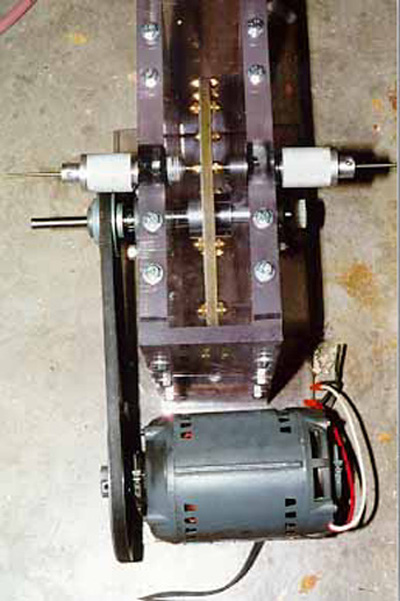

Rotary Gap Construction Details

Rotary Gap Construction Details

- Side Plates -------------- 1" thick acrylic, 14"x14" square

- End Plates --------------- 1/2" thick polycarbonate

- Base Plate --------------- 1/2" thick polycarbonate

- Rotor (disk) ------------- 1/2" thick G-10 (Epoxy-fiberglass composite)

- Shaft ------------------- 1/2" electric motor shafting

- Stationary electrodes ---- 1/8" TIG welding electrodes

- Electrode holders -------- turned aluminum

- Electrode holder holders - turned phenolic resin plastic (bakelite)

- Bearings ----------------- Sealed ball bearings

- Pulleys ------------------ Salvaged from furnace blower

- Electric motor ----------- (Not the one shown on any photos) 1 HP 10,000 RPM

Carter motor 110v AC/DC

- Moving Electrodes -------- 24 1/4-20 Brass Acorn nuts (2 each side)

I designed the rotary gap mechanism this way so that it would satisfy several

requirements.

- Ability to change motors relatively easily

- High electrode velocity

- High break rate

- Bulletproof enclosure to contain exploding disks, etc.

- The electrode holders must be able to get extremely hot (300F, ~175C)

- The electrodes must have adequate heat dissipation available.

- Variable speed

To achieve these goals, I opted for a totally enclosed disk, and selected

materials that wouldn't be affected by the heat that they would encounter.

The large motor shown in the photos is not the one that I finally settled upon.

It was single speed induction motor, and therefore I could not adjust its

speed. I used it because it was handy and I had no other motor at the time.

The motor that I am using now is much more powerful and faster as well. I can

vary the speed of the disk from 0 to about 5000 rpm, which is more than fast

enough.

Because the electrodes would get hot when running at high power levels, I

decided to hold them with large aluminum holders. They are turned from 1.5"

aluminum rod. I was also concerned that they would get hot enough to soften

the acrylic side plates. To get around the problem, I made some phenolic

bushings from pieces that I had around the garage.

I have used this rotary gap in coil operation and it works quite well. It is

quiet, which is Oh So Important when running a tesla coil :-) (In case you

aren't aware of it, a tesla coil is extremely noisy.)

Return to main rotary gap page

Return to homepage

This page has been accessed

times since 3/2/97 and was last updated

.